Recently, I wrote a blog discussing communication during the commissioning process. That post discussed effective means of communication, how to stay well informed of project updates, and the importance of developing a rapport with all parties. Writing the piece made me think about the best practices a commissioning authority (CxA) can integrate into every stage of the commissioning process to be more effective. This post will discuss some of the best practices I’ve learned to use during the critical construction phase.

Hold a Great Kickoff Meeting

If executed properly, the project team should leave the kickoff meeting feeling confident that the CxA is there to help ensure the project succeeds. In addition to always bringing doughnuts for the team (who doesn’t perk up at the sight of sweet treats?), best practices for the kickoff meeting include:

- Schedule the meeting carefully. It shouldn’t happen too early, as contractors could forget about the Cx process if too much time goes by. But if it happens when equipment is already being installed, you’ll have missed critical opportunities to review submittals and inform the process. Find a time when contractors are on site and construction has begun, but equipment is not yet being installed.

- It may seem obvious, but the kickoff meeting should include a full review of the Cx process. Provide a master list of equipment to be commissioned, testing prerequisites and durations, and pre-functional checklists so that team members fully understand what to expect.

- Maintain meeting momentum by walking the site after the meeting, shaking hands with installation contractors, show genuine interest in their work and better understand the project through focused observation.

CxA Completes Pre-Functional Checklists

The CxA should take responsibility for completing pre-functional checklist documentation Instead of relying on installation contractors for the task. The CxA is best positioned to verify proper installation early and prevent systemic problems and serve most effectively as an advocate for the owner. My next blog will elaborate on this topic in greater detail.

Be Part of the Solution

Project teams appreciate commissioning authorities who do more than generate lists of issues – they should also try to be part of the resolution. The commissioning deficiencies log is an essential communication tool for tracking deficiencies that cannot be immediately resolved. Each deficiency is assigned to the appropriate responsible team member. The log should clearly define each deficiency and provide a recommendation to help resolve the deficiency. While on site completing the pre-functional checklist, the CxA should make a point of building rapport with the project team members who are responsible for equipment installation. This way, when deficiencies are discovered, the CxA knows who to seek out to discuss the deficiency and either resolve it on the spot or provide a recommendation to expedite resolution.

Customize Functional Performance Testing

Functional Performance Testing (FPT) documentation should be completed after submittals have been approved. It should reflect specific manufacturer installation and operational requirements as well as test procedures developed from years of commissioning experience. Use specific control sequences developed by the design engineer to test how equipment responds to status changes, such as transitioning from heating to cooling or enabling an economizer mode. Does the equipment setback when set points are achieved? Will equipment designated for backup power enable during an emergency power failure? Is the direct digital controls interface complete and without error? These questions and more are answered when the CxA has robust FPT documentation, executes testing procedures in a systematic manner, and clearly documents the results so testing can be repeated in the future during recommissioning.

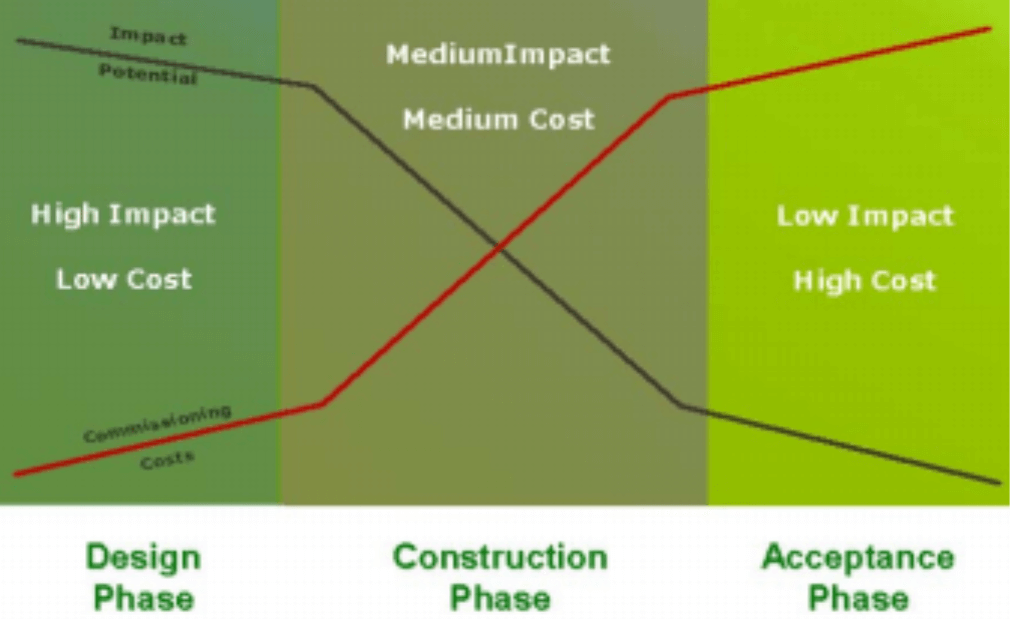

The value of commissioning is best achieved in the design phase, when high impact and low costs are most advantageous as detailed in the graph above. As the project moves into the construction phase cost avoidance becomes more expensive. The best practices mentioned here can help ensure the project team is well informed, costly equipment failures are avoided and the project is setup for a successful acceptance and testing phase.