In BSL-3 facilities, maintaining facility performance is crucial to protecting workers, the community, and critical research. Hiring a commissioning provider to inspect your facility is a good strategy, since those specializing in biocontainment labs – like Cornerstone Commissioning – know the architectural and mechanical integrity issues to look for. Experienced biocontainment commissioning teams can uncover the common and not-so-common facility problems and recommend ways to resolve them.

Are there easily-spotted room integrity issues that you could see on your own just by looking around the lab? Absolutely. We’ve outlined the most common ones below.

1. Dirt Trace

The upkeep and maintenance of the secondary containment barrier is one of the most important aspects in BSL-3 lab annual performance verifications. Just as the primary containment elements must be verified to be operating correctly and certified (biosafety cabinets, HEPA filters and freezers), the secondary containment barrier has to be inspected to ensure that the only outside air entering the BSL-3 is from the HVAC supply air diffuser and around the doors.

One of the easiest BSL-3 room integrity issues to spot is known as “dirt trace,” and can be found on any joint, gap, fixture or penetration in the lab. As the sealant and caulking dries and shrinks over time, it creates small crevices and pin holes in the secondary containment barrier.

One of the easiest BSL-3 room integrity issues to spot is known as “dirt trace,” and can be found on any joint, gap, fixture or penetration in the lab. As the sealant and caulking dries and shrinks over time, it creates small crevices and pin holes in the secondary containment barrier.

The BSL-3 lab is typically under a high negative pressure within relation to its surrounding areas. The HVAC system serving the lab will draw air from anywhere it can, including the area between the finished walls and ceilings, the deck above and the adjacent spaces. Those spaces have leftover construction dust and debris that is being pulled into the laboratory – hence “dirt trace.”

Since most BSL-3 spaces are painted white, this makes for an easy-to-spot issue that appears as a black streak.

The streaks can be faint or clear, depending on the pressure of the lab and the size of the crack or gap in the sealant.

The areas that show dirt traces should be decontaminated and wiped clean before being repaired.

2. Recessed lighting

Any way you slice it, recessed lighting is bad for BSL-3. Even the best installation is bound to have integrity issues. It’s better to choose surface mount lighting.

Any way you slice it, recessed lighting is bad for BSL-3. Even the best installation is bound to have integrity issues. It’s better to choose surface mount lighting.

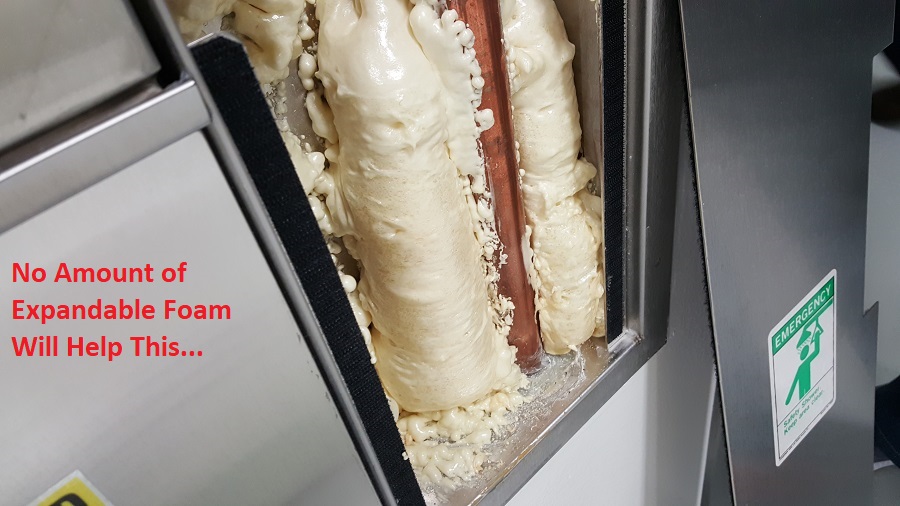

3. Recessed emergency shower handle

Same deal as above; recessed anything in a BSL-3 is bound to cause room integrity issues.

4. Tel/data jack & outlets

The image on the left shows a poorly sealed tel / data jack. The image on the right is better and won’t leak.

5. Fire sprinkler head

Not all contractors know how to properly seal off fire sprinkler heads, and therefore many of them leak, causing room integrity issues.

Summary

If any of the above seem to be a problem in your facility right now, contact us and we’ll schedule a more formal facility inspection for you.

While discovering room integrity issues can be alarming, they don’t need to bring your biocontainment lab operations to a screeching halt. Some issues can be resolved with simple solutions or by adjusting standard operating procedures to bridge the gap in facility performance. All in all, it’s about knowing how best to manage or mitigate whatever risks are present so that laboratory operations can continue.